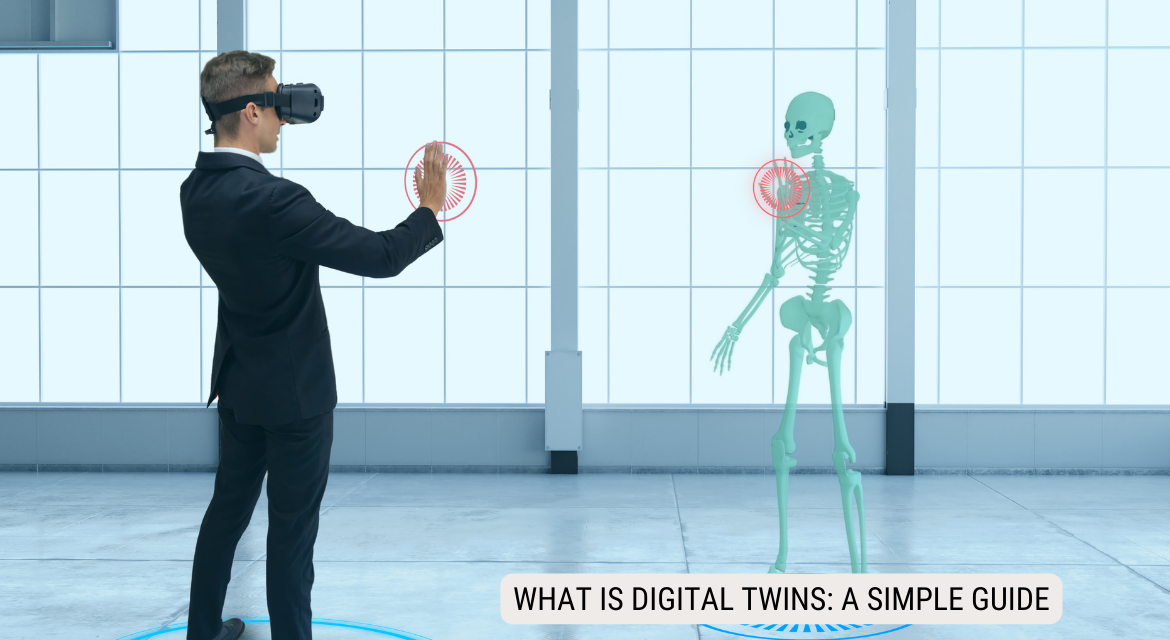

In the fast-changing world of technology, digital twins are becoming increasingly important in various industries. But what exactly are digital twins? Let’s break it down.

What is a Digital Twin?

It is an electronic duplicate or digital version of a tangible item, procedure, or framework. It resembles having a digital representation of a genuine object that exists in reverse. IoT devices, sensors, and other data sources generate this digital picture, which makes real-time analysis, modelling, and monitoring possible.

How Do Digital Twins Work?

Digital twins are virtual versions of real-world objects or systems created using advanced analytics and simulation techniques. Data is collected from the object’s real-life counterpart to create a digital twin, including information about its condition, operation, environment, and more. Continuously updating the digital twin with new data makes it a powerful tool for understanding, predicting, and optimising the object or system it represents.

Applications of Digital Twins:

They have numerous applications across various industries.

- Manufacturing: It can visualize production processes, optimize equipment performance, and predict maintenance needs, which results in increased efficiency and reduced downtime.

- Healthcare: In healthcare, It can simulate patient conditions, personalise treatment plans, and model surgical procedures to improve outcomes and reduce risks.

- Smart Cities can be applied to model city infrastructure, monitor traffic flow, and optimise energy usage, leading to more sustainable and livable urban environments.

- Aerospace: In the field of aerospace, digital twin technology can be utilised to simulate aircraft performance, forecast maintenance issues, optimise fuel efficiency, and enhance safety while reducing costs.

Benefits:

The benefits of it include the following:

- Improved Decision-Making: Digital twins offer real-time insights and predictive analytics, which empower individuals to make better-informed decisions.

- Optimised Performance: Digital twins are digital replicas of physical assets, processes, and systems used for analysis, monitoring, and optimisation. They can increase efficiency and productivity.

- Reduced Costs: By utilising it to forecast maintenance needs and optimise operations, maintenance expenses can be reduced, downtime prevented, and waste minimised.

- Innovation: Digital twins allow for experimentation, simulation, and scenario planning in a virtual environment, promoting innovation without risk.

They are changing the game when it comes to designing, monitoring, and optimising the physical world. They use data and simulation to improve various industries and have the potential to revolutionise the way we live and work. Overall, this is an effective tool for driving advancements and innovation.